Wechat/whatsapp:

+86 15189741851

Email address:

info@yancymachinery.com

Add:

No. 55-57, Shuangguifang, South Street, Zhonglou District, Changzhou

Dry Mix Mortar Plant Manufacturer In China

Supply Customized Solution for 1-100T/H Production Line. Full Automatic Production Line, Will Help You Save More.

As a professional dry mix mortar plant manufacturerwith many models of machines and annual output from 30,000 tons to 800,000 tons, it has a professional technical and service team. Can develop turnkey solutions for you, so that you pre-sales worry, after-sales rest assured.

Semi-automatic dry mix mortar production line output is 1-10t/h, can be said to be small output, big return, very suitable for small and medium-sized investors.

Here we list three best-selling dry mix mortar plants. The larger the mixer, the higher the output.

Capacity | 1-6t/h |

Mixer Model | M500, M1000, M2000, M3000 |

Mixer Power | 5.5-15kw |

Control System | Semi-automatic with electric control cabinet |

Capacity | 6-8t/h |

Mixer Model | M3000, M4000 |

Mixer Power | 15-20kw |

Control System | Semi-automatic with electric control cabinet |

Capacity | 8-12t/h |

Mixer Model | M2 cubic |

Mixer Power | 11kw |

Control System | Semi-automatic |

There are many types of automatic dry mix mortar plant, can better meet your needs. From sand crushing, screening, drying to raw material self-moving metering, automatic mixing, automatic packaging, the whole process is controlled by intelligent programming, easy to operate, saves staff costs, improves economic efficiency.

Capacity | 5-10t/h |

Mixer Model | 2 cubic |

Mixer Power | 11kw |

Control System | Semi-automatic; Full-automatic |

Capacity | 10-20t/h |

Mixer Model | 3 cubic |

Mixer Power | 18.5kw |

Control System | Full-automatic |

Capacity | 20-30t/h |

Mixer Model | 4 cubic |

Mixer Power | 22-30kw |

Control System | Full-automatic |

Capacity | 60t/h |

Mixer Model | 6 cubic |

Mixer Power | 45kw |

Control System | Full-automatic |

After years of stable development, FUREIN has become a powerful dry mortar plant manufacturer.

A dry mortar plant that is familiar with your market can help you save even more.

Furein’s dry mix mortar manufacturing plant is exported to more than 100 countries and regions, and professional engineers can come to your country to install machines and train workers.

The application field of dry mix mortar manufacturing plant is very wide and has been well received by customers.

Furein has 300+ successful cases for nearly 3 years, each case is unique, if you need it can guide you in the right direction, tailor-made production solutions.

We have 150+ suppliers in China who can provide you with standardized spare parts. If your dry mix mortar plant needs to replace spare parts during use, you can easily buy spare parts in your country and replace them.

·What Kind Of Mortar Can Be Produced By Dry Mix Mortar Plant?

·Working Principle of Dry Mix Mortar Plant

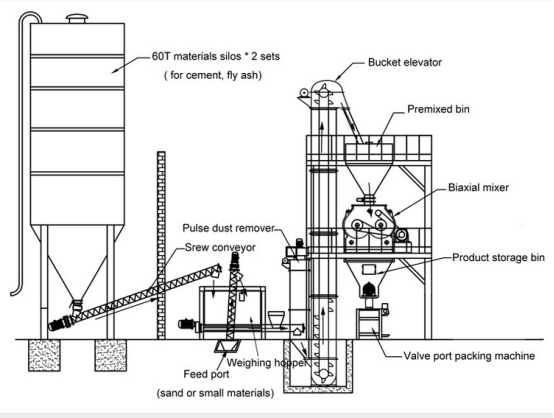

Simple, material after outdoor bucket elevator was promoted to the raw materials warehouse(premix bin), and then delivery the material to the weighing system, then after weighing the material enter indoor bucket elevator through screw conveyor, and then through the screw conveyor into the dry mortar mixer, and then the material falls into the mixer to mixing, mixed materials into finished products bin, you can choose the finished material in bulk or in bags.

With an annual output of about 20,000 tons of dry mortar production line, 3-6 raw material silos are generally used, among which two large tanks are used to hold bulk cement and fly ash, and the rest small tanks are used to hold light calcium, heavy calcium, sand, small materials, etc.

Bulk cement and fly ash into the tank do not need to bucket elevator equipment, relying on the pump truck drive. Bulk fly ash silo is generally cylindrical bracket structure, the upper part of which is equipped with dust removal equipment to prevent dust leakage, the lower part is equipped with arch breaking device to prevent powder agglomeration, so that the powder is discharged smoothly, and equipped with material level sensing equipment, you can know the use of materials in the silo at any time.

Light calcium, heavy calcium, sand, small material and so on need to use bucket elevator lift into the small tank. The weighing system, with the cooperation of the screw conveyor, transfers the raw materials in the silo into the metering silo, and realizes the control of raw materials through the data feedback of the sensor.

After measuring the material, through the screw conveyor into the bucket elevator, lift to the dry mortar mixing machine. The mixer machine is of pneumatic open door type, which can quickly put the materials to be mixed into the no-gravity mixer and realize the continuous production of dry mortar.